еЬЯжЫЬжЧ•, 10жЬИ 2nd, 2010...4:15 PM

ZORI at Wakuda Shouten

Reading time: About 3 minutes

ZORI at Wakuda ShoutenIn the city of Asakusa, there are still many businesses which handle traditional Japanese goods. We visited Wakuda Shouten to see how some of these goods are made and sent out to consumers. Wakuda Shouten is a zori (Japanese slippers usually worn with kimono) company which began soon after the war ended in Japan. The company continues to produce high quality handmade zori with the help of experts in different areas.

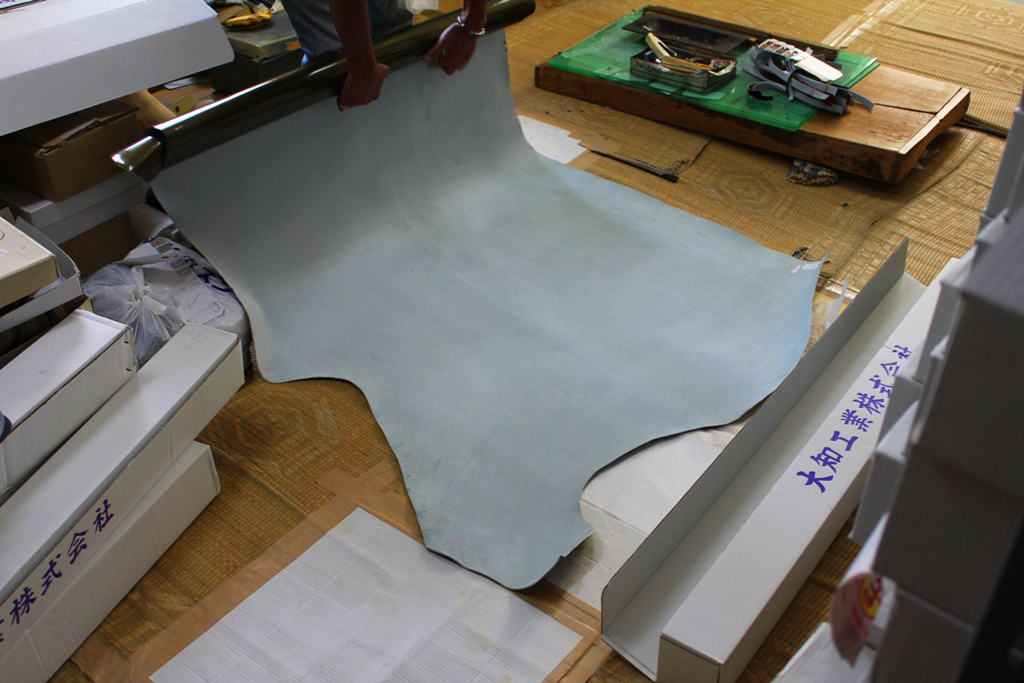

The making of a traditional zori slipper requires a lot of work and effort. There are specialists for each step in the whole process, and Wakuda Shouten works with these specialized companies to produce the products. First, after they have received an order from a customer, the company selects and buys the materials which are to be used for the zori. Wakuda Shouten only uses real cow leather for their products.

These leather materials are dyed and processed for the zori by craftsmen in places such as Kyoto which is famous for its material production.

Then, these materials that have been sent to the company are cut out according to the design of the zori. At Wakuda Shouten, the design and combination of the leather materials are thought out by a craftsman who works for them. The friendly old man, while cutting the beautiful leather of deep purple into perfectly equal strips, told us that even just running the blade across materials cannot be done without much experience. Being completely fascinated with the beautiful colors and patterns cleverly designed on the finished products, we asked him how he learned all these wonderful techniques. He answered from his workspace how he began doing this since he was a teenager, and that he learned through his senses through many years of experience without formal education.

After the design has been though out and the materials have been cut out, the parts are then sent off to different companies with different expertise. There is one that applies the leather around the framing of the slippers which constitutes of several layers, and another that specializes in the hanao (the belt that straps down the slippers to the feet). The completed parts are then sent back for them to be put into the hands of, this time, workers who precisely put together the different parts. The final products return back to Wakuda Shouten for the last time to be shipped out to various sellers and department stores all over Japan.

Off to the side, the hanao (foot strap) craftsmen as well as Mr.Wakuda, through years of experience, can tell the size of the zouri sandals just by slipping their left hand into it. The funny thing is, it only works with the left hand and not the right. Wakuda Shouten also makes trips to the Japanese coming of age ceremonies and makes adjustments of hanao.

Nowadays, many zori slippers are mass produced using cheap artificial materials for easier production and consumption. Nevertheless, this Wakuda Shouten continues with the traditional way, borrowing the hands of craftsmen and using high quality materials. Although it is time consuming and costly, the members running the company seemed completely satisfied and proud of what they do. Mr.Wakuda, the man currently running the company, said as he picked up one of the finished zori, вАЬI think this can only be done by our company.вАЭ Indeed, the precious zori slippers which were beautifully aligned on their shelves all seemed to me like jewels unlike any other.

вЦ†Related Post

*Research on a Kimono Market

Leave a Reply